chlorinated polyethylene CPE135A

Chlorinated polyethylene thermoplastic resin is an excellent impact modifier widely used in PVC extrusion and injection molding (including profile, plate and pipe

Description:

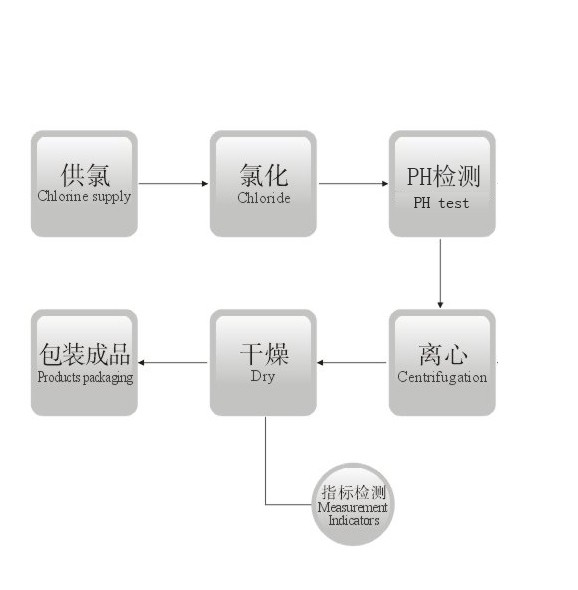

Chlorinated polyethylene (CPE) is made from high density polyethylene(HDPE) replaced by chlorination reaction of elastic polymer materials. The appearance is non-toxic and odorless white powder. Have excellent toughness, weather resistance, oil resistance, flame retardant, coloring resistance, chemical and other properties, is compatible with plastics, rubber, excellent filling properties. Depending on the product performance, CPE can be used as impact modifiers, plastic modified solubilizer and synthetic special rubber..

INDEX SHEET:

Items | UNIT | INDEX |

Chlorine content | % | 35±1 |

Remains crystallinity | % | ≤2 |

Volatile Matter component | % | ≤0.5 |

Rate of filtration(40 mesh) | % | ≥98 |

Shore Hardness A | ° | ≤65 |

Thermal decomposition temperature | ° | ≥165 |

Bulk density | g/cm3 | ≥0.5 |

Tearing strength | Mpa | ≥8.0 |

Impurity particle | PC/50g | <10 |

Whiteness R457 | ° | ≥86 |

Applicants:

Used in impact modification of plastic profiled material, pipe, sheet material, sheet material, valve, CPVC pipe of hot water, and electrical pipe

Storage & transportation:

Kept in dry and ventilating place, avoid moisture, insolation and fire. No mix with other chemicals.

Packing:

PP woven bag. net wt 25kg.

INQUIRY

CATEGORIES

LATEST NEWS

- Introducing High-Performance ASA C

-

How to solve the issue of PVC foam

How to solve the issue of PVC foam boards:middle

- Difference Between Ethylene and Ca

CONTACT US

Contact:

Phone: 0086 19526969938

Tel:

Email: info@krtchem.com

Add: Economic Development Zone, Linqu County, Weifang City, Shandong Province, China