News

Differences Between Calcium Carbide PVC Resin and Ethylene PVC Resin

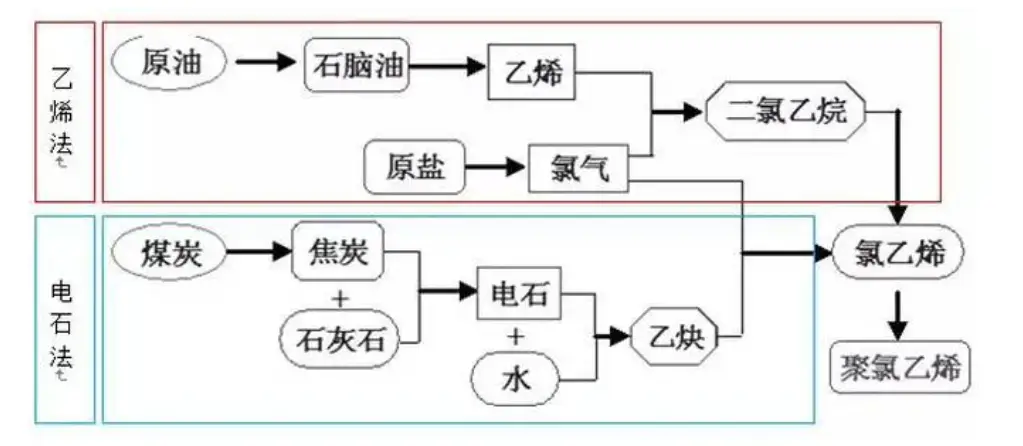

Differences in Raw Materials:

Ethylene-based PVC uses ethylene and chlorine, with ethylene costs accounting for about 65% of production costs, heavily influenced by crude oil prices. Calcium carbide-based PVC uses calcium carbide, hydrogen chloride, and electricity, with calcium carbide costs making up about 70% of production costs, mainly depending on electricity prices.

Price Differences:

Due to China's energy structure, calcium carbide PVC dominates the market with 79.76%, while ethylene PVC holds 20.24%. Prices of ethylene PVC are generally higher due to its raw material and process advantages, although its trends are influenced by calcium carbide PVC prices.

Performance Differences:

Calcium carbide PVC resin has a lower molecular weight and a wider molecular weight distribution compared to ethylene PVC resin, impacting heat stability and mechanical strength.

Calcium carbide PVC dry blend has better plasticization performance, showing higher plasticization torque, shorter plasticization time, and lower balance torque.

Application Differences:

Both types of resin are used in similar applications but with different processes. Ethylene PVC is favored for high-end products like automotive interiors, transparent sheets, and films, while calcium carbide PVC is used mainly for pipes and building materials. Generally, ethylene PVC is considered superior in quality.

ALL KIND OF PVC RESIN ARE IN HOT SELLING,

WELCOME FOR YOUR ORDER AND INQUIRY: JOAN@KRTCHEM.COM

RELATED NEWS

- Introduction to chlorinated polyethylene 2020-06-04

- PVC Processing Additives Selection Principle 2022-03-08

- PVC impact modifier classification 2020-03-11

- CPE vs Acrylic impact modifier for PVC pipes 2021-05-09

- Analysis of PVC foaming regulator and Regular Grades 2018-01-25

CATEGORIES

LATEST NEWS

- Introducing High-Performance ASA C

-

How to solve the issue of PVC foam

How to solve the issue of PVC foam boards:middle

- Difference Between Ethylene and Ca

CONTACT US

Contact:

Phone: 0086 19526969938

Tel:

Email: info@krtchem.com

Add: Economic Development Zone, Linqu County, Weifang City, Shandong Province, China