News

MBS Impact Modifiers vs. Acrylic Impact Modifiers

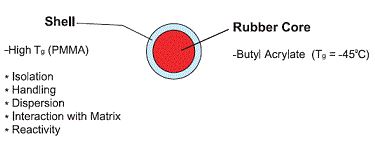

A representation of a typical core-shell impact modifier is provided below.

Typical Core-Shell Impact Modifier

These materials usually have a low Tg rubber core, such as butyl acrylate or butadiene, with a poly (methyl methacrylate) PMMA shell. Examples of commercially available core-shell impact modifiers include PARALOID™ from Dow Chemical and Clearstrength® from Arkema.

One of the primary advantages offered by the core-shell impact modifier approach is that a pre-determined particle size is provided. However, the impact modifier must be appropriately dispersed in and coupled to the matrix polymer in order to be effective for toughening engineering plastics.

This coupling can result from the physical interaction of the shell matrix with the matrix or by chemical reaction. The most obvious route to achieve that is to combine reactive moieties into the shell chains during fabrication by emulsion polymerization. Those reactive moieties, then, subsequently react with the matrix during melt processing.

MBS Impact Modifiers vs. Acrylic Impact Modifiers

| Methacrylate Butadiene Styrene (MBS) | Acrylic Impact Modifiers (AIM) |

|  |

Benefits:

| Benefits:

|

Applications:

| Applications:

|

MBS Core-shell impact modifiers are designed to provide exceptional cold-temperature impact in a wide range of Engineering Plastics such as polycarbonate, polycarbonate alloys (PC/ABS, PC/PBT), and polyesters.

Core-shell impact modifier imparts better low-temperature impact strength, mold-in colorability, and thermal stability to polycarbonate than any other acrylic available in the market.

RELATED NEWS

- Introduction to chlorinated polyethylene 2020-06-04

- PVC Processing Additives Selection Principle 2022-03-08

- PVC impact modifier classification 2020-03-11

- CPE vs Acrylic impact modifier for PVC pipes 2021-05-09

- Analysis of PVC foaming regulator and Regular Grades 2018-01-25

CATEGORIES

LATEST NEWS

-

DOTP vs DOP Plasticizer – Key Diff

DOTP vs DOP, PVC plasticizer, DOTP plasticizer s

- PVC Foaming Regulators: Function,

-

Acrylic Impact Modifier for Rigid

acrylic impact modifier, AIM for PVC, PVC toughn

CONTACT US

Contact:

Phone: 0086 19526969938

Tel:

Email: info@krtchem.com

Add: Economic Development Zone, Linqu County, Weifang City, Shandong Province, China