News

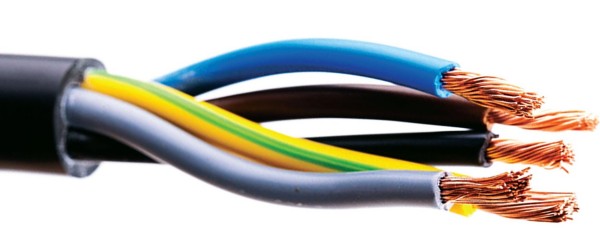

Rubber type chlorinated polyethylene (CM135B) uses in wire and cable

Chlorinated Polyethylene (CM) is a high-molecular random chloride obtained by replacing the hydrogen atoms on the secondary carbon atoms in the molecular structure of high-density polyethylene (HDPE) with chlorine atoms. CM with a chlorine mass fraction of about 35% does not contain double

key, so it has the advantages of high strength, good elasticity, flame retardancy, oil resistance, solvent resistance, ozone resistance, heat aging resistance, weather resistance, good processing performance, high filling, large output, and low price [1], which has gradually replaced the price Expensive CR, CSM, EPDM become the main raw materials for wire and cable sheathing. In this paper, the regression design method is used to study the influence of vulcanizing agent DCP and reinforcing filler carbon black on the physical and mechanical properties of cM135B, and the results are applied to marine wire and cable.

The results show that: within the test range, with the increase of the amount of DCP, the tensile strength reached the highest value and began to decrease, the 100V0 modulus and hardness increased significantly, and the tear strength, resilience and elongation at break decreased sharply; With the increase of the amount of carbon black, the tensile strength and tear strength gradually increased to reach the maximum value and then gradually decreased, the elongation at break and resilience decreased sharply, and the 100 modulus and hardness increased significantly. Therefore, the comprehensive performance of the rubber compound is better when the amount of DCP is between 3.5 and 4.5 parts and the amount of carbon black is between 40 and 60 parts, which meets and exceeds the national standard requirements for marine wire and cable.

RELATED NEWS

- Introduction to chlorinated polyethylene 2020-06-04

- PVC Processing Additives Selection Principle 2022-03-08

- PVC impact modifier classification 2020-03-11

- CPE vs Acrylic impact modifier for PVC pipes 2021-05-09

- Analysis of PVC foaming regulator and Regular Grades 2018-01-25

CATEGORIES

LATEST NEWS

-

Why ASA Resin Is the Preferred Mat

ASA resin is widely used for outdoor profiles an

-

DOTP vs DOP Plasticizer – Key Diff

DOTP vs DOP, PVC plasticizer, DOTP plasticizer s

- PVC Foaming Regulators: Function,

CONTACT US

Contact:

Phone: 0086 19526969938

Tel:

Email: info@krtchem.com

Add: Economic Development Zone, Linqu County, Weifang City, Shandong Province, China